Hardwares

- Home

- Hardwares

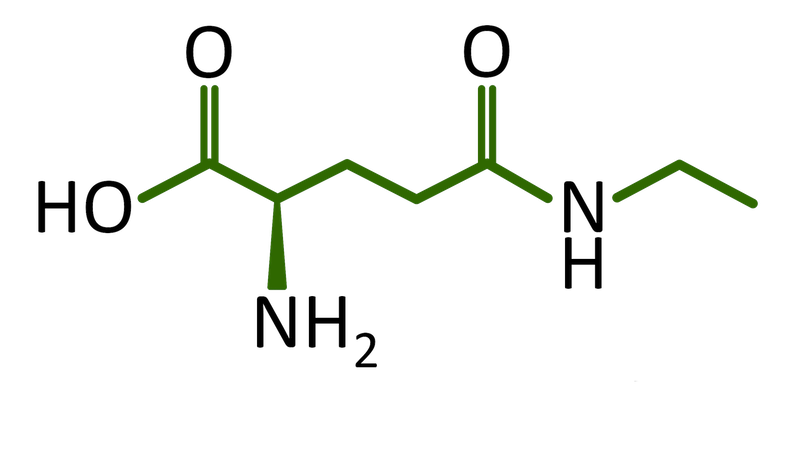

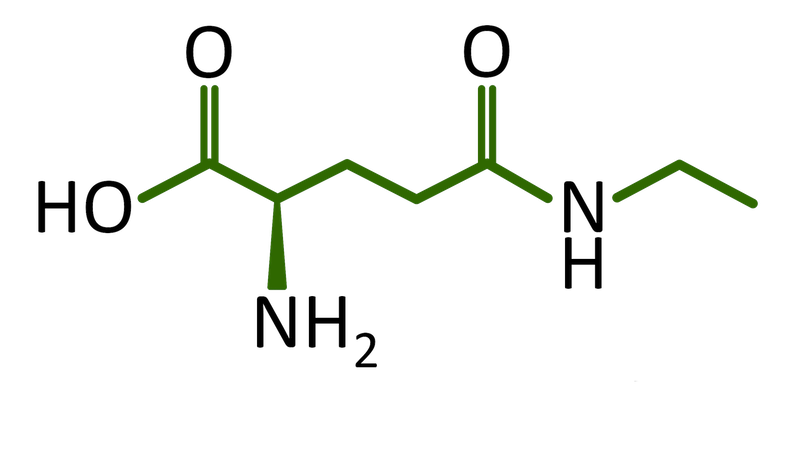

The objective of our project is to alleviate anxiety using theanine as a safe food grade additive or supplement. The safety of using theanine is supported by research literatures, expert advice from Human Practices interviews, and also justified by national and international safety guidelines and regulations.

Upon successful synthesis of theanine from our de novo synthesis pathway, the substance can be extracted and purified from the bacteria fermentation culture, which is nowadays a common practice in industry. After extraction, theanine will be in a powder form, ready to be implemented into daily uses.

However, simply obtaining the substance doesn’t stop anxiety from influencing the students. In fact, through our survey, we learned that even though a majority of people have anxiety related symptoms, they are not actively taking food supplements to try to improve the conditions.

In developing hardwares, we hope to find methods to

1) facilitate the absorption of the theanine, and

2) enhance user experience and fun to promote using theanine.

We have devised several plans and have developed some hardware in these directions.

Firstly, theanine has very similar structural feature to glutamate, and is a water-soluble amino acid. We plan to create a theanine humidifier (or nebulizer, as known on the US market) that transforms solution of theanine into theanine containing mists, allowing people to absorb theanine through the respiratory mucosa.

The idea was proposed during the brainstorming stage, and later during our survey questionnaires, the users’ input proved this unconventional product can be welcomed. About 1 out of 4 people likes using a new device such as a humidifier to take in theanine.

To achieve this goal, we disassembled commercially available humidifiers to understand their internal structures. The core component of the humidifier is an ultrasonic humidification module, which uses ultrasonics to vibrate the water into very fine droplets that are then sprayed out. By inhaling the mist containing theanine, people can absorb theanine through their respiratory tract. We chose to use a 3.7V 18650 battery, a 3.7V to 5V charging-discharge boost module, and a 5V humidifier atomization module. This is our circuit design:

Based on our circuit design, we conducted 3D modeling in Solidworks 2023. Our first version of the 3D model divides the entire device into two parts: the main body for storing electronic components and a clasp made from a Corning ™ 50ml centrifuge tube cap, which can be replaced with a Corning ™ 50ml centrifuge tube containing the theanine solution. The main body includes compartments for the 18650 battery and the circuit board. The battery compartment houses an 18650 battery holder, which also serves as the grip for handling; the circuit board compartment contains the boost module and the humidifier circuit board. We drilled a hole on the side of the circuit board compartment, through which the interface of the ultrasonic humidifier plate connects to the humidifier circuit board. We first drilled a hole in a centrifuge tube cap, then fixed the ultrasonic humidifier plate to the cap with hot glue and attached the cap to the clasp integrated with the main body using hot glue. Here is our Solidworks 3D design: We also designed a ring to be placed inside the Corning ™ centrifuge tube, which holds a cotton swab that absorbs the theanine. We used white PLA as the material for 3D printing all the components.

Fig1: Humidifier body structure diagram

Fig. 2 Parts of the humidifier

Many teams have worked on synthetic biological therapeutics, such as substances for anti-depression of Japan-United in 2023. We believe a hand-held humidifier design can broaden the choices of other iGEM teams for implementing their syn-bio products and inspire new ways for delivering the cure and care to the users.

According to our research, if the water atomized by ultrasonic humidifiers is impure, there is a risk of causing diseases like tuberculosis and pneumonia. Therefore, we decided to fill and seal all theanine solution refills in a cleanroom environment and use ultraviolet disinfection to minimize the risk of lung infections caused by impurities in the solution.

Fig 3. 3D printed humidifier framework, with battery and circuit installed.

After the first version of the humidifier was successfully printed, the circuit assembled, and it began emitting mist, we started to consider improvements in the product's ergonomic design. To enhance the enclosure of the circuit, we added a cover with a small hole to the prototype, into which a 3D-printed stick can be inserted to serve as the switch for the humidifier module. To increase the comfort of holding the humidifier, we added rounded edges to the grip and the top of the humidifier. Considering that some people might place the humidifier on a table during use, we designed a circular base for the humidifier.

Fig 4. Student user tested the humidifier and shared user experience and improvement feedbacks

According to our expert interviews, we discovered that while absorbing theanine through the respiratory mucosa is possible, it's not the most efficient method. Absorption through the digestive tract is significantly more effective. As a result, we began developing theanine candies, a product similar to coffee candies.

1. The problem

Users, especially our peers, love candies. Preliminary survey results indicate that hard tablet candies are the most preferred product form, with an expected user preference of 73.9%. Flavoring additives are necessary in the making process, but they often lack the proper texture and stickiness to combine with other powder ingredients to form a hard candy tablet. We test different recipes, ingredients, and devices to find a proper method for hard tablet candy making, and also hoping this experience would help other iGEMers in developing new products.

2. Safety Considerations

We put safety as our first priority. All ingredients used are food-grade. The food grade theanine was sourced from certified commercial suppliers.

Candy production attempts were conducted in kitchens to ensure safety, away from laboratory settings to avoid exposure to hazardous chemicals, microorganisms, and contaminated lab environments.

3. Production Method Selection

Mainstream methods in the market include wet granulation, dry granulation (high-speed stirring granulation, comparison of wet and dry granulation in preparing Fuling polysaccharide tablets), and direct powder compression.

Direct powder compression was selected as the trial production method due to its compatibility with the powdered crystal form of theanine and the convenience for future production.

We adopted standard industrial ratios for additives. The filler agent takes 20% to 40% of the total composition, while the lubricant takes 0.5% to 2%. Theanine takes 5%. The rest is balanced with sugar, flavor enhancers, and colorants.

4. Preliminary Attempts and Issues

The initial attempt used kitchen corn starch as the filler and granulated sugar as the main ingredient, without any lubricant, and a manual hammer press mold for compression. The resulting product lacked sufficient hardness and discernible texture. When touched and squeezed by fingers, they lack sufficient hardness and were easily smashed into powders. We studied the industrial production methods and concluded that the main factor is low compression pressure.

5. Improvement Measures

We obtained a new compression device capable of providing a continuous pressure output of 0.4 tons. Meanwhile, microcrystalline cellulose was chosen as the filler, and magnesium stearate as the lubricant based on literature review (An Analysis of the Application of Microcrystalline Cellulose (CMC) in Powder Direct Compression Technology). Glucose, food coloring, and flavoring agents were added to the formulation. Additionally, four mature products from the market were selected for flavor simulation: milk powder, instant fruit juice, coffee powder, and milk tea powder. Among these additives, milk tea powder has the best shape forming capability, resulting the hardest tablet.

6. Product Specifications

After a few test, we made candy tablet each at 1 gram with 5% theanine. The final dosage is 50 mg of theanine in each tablet. According to national and international guidelines, the safety limits for theanine as a food additive and the recommended intake is 400 mg per day (QB/T4263-2011). Therefore, a recommended daily intake of 8 pieces per person is suggested.

A candy dispenser that limits your daily intake

According to the Third Industry Standard of the People's Republic of China, QB/T4263-2011, the maximum daily intake of theanine is 400mg. Based on this standard, we have developed a formula for theanine sugar, similar to coffee sugar. To ensure that the theanine dosage in the candies consumed by users does not exceed the safe intake standards, we plan to design a quantitative sugar dispenser to control the candy intake over 24 hours, providing a maximum of eight candies per day, with each candy containing 50mg of theanine.

A mechanical timer and ratchet mechanism

We first considered using electronic timers. There exist various types of products on the market implementing electronic timer for pill boxes. The problem is that the timer in these implementations can only serve as a reminder. They alter the user to take their pill at certain times, but they do not have a function to stop the users from taking more than necessary. If we compound a timer with other electronic locks, the device would become too expensive for a candy box.

The candy dispenser, Chorno, is thus designed to be driven by a mechanical timer from a small household fan, at a cost of only 1.5 US dollar. When users want a piece of theanine candy, they can rotate the dispenser's outer box. This action also turns the timer and candy storage compartment at the same time, and when turned to the candy outlet, the timer is also set to two hours. The ratchet mechanism in the timer rotor ensures that reverse rotation of the candy box won’t move the candy outlet. It can only move with the timer so that a user has to wait. The dispenser can hold up to 24 pieces of our developed theanine sugar.

The entire theanine candy dispenser consists of three parts: the mechanical timer, the candy pushing disc, and the dispenser shell. The timer is available in 60-minute and 120-minute options, determining how soon users can access another candy. The candy pushing disc moves a piece of candy to the dispenser opening and is then pushed back to its starting position by the fan timer. The dispenser shell, made up of an upper and lower part, not only stores the candies but also facilitates the rotation of the entire mechanical structure for the user. A small round plate that can be screwed on secures the candy box and the pushing disc together.

Fig1: developed path of Theanine candy dispenser

Fig2. All parts of the final version of the Theanine candy dispenser

Fig3. Theanine candy were put in dispenser.

Watch our video in Solidworks to see how the dispenser works to stop candy release before the timer ends.

Linking to iGEM video universe to watch the video: https://video.igem.org/w/rrGN1TwyTaq8ekFQYnoXBS

All the design files in Solidworks can be obtained from us upon request.